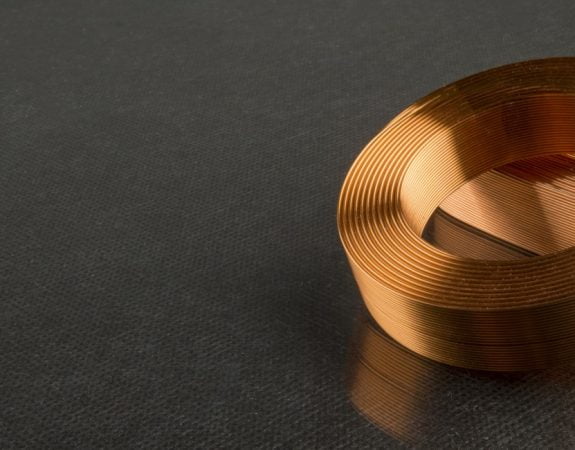

We offer prototype and production services for many types of coil wound products ranging from miniature wound components and assemblies up to 100 VA transformers. We have a diverse customer base and supply the differing needs of each specialist sector – aeronautical, audio, automotive, communications, hydraulics, military, pneumatics, power supplies, scientific, medical and many others.

Low, medium and high volume requirements of precision wound components and assembly parts are welcome at NDE, with batches of 5 – 25,000 units per week on typical production runs. Our production uses fully automated manufacture where appropriate. For small and medium volume batches, universal winding facilities are available using various types of machine that can minimise tooling and setting up costs.